Print your art and patterns on over 100 fabrics with different properties constructions and uses all handmade with no minimum and ready in 1-2 days. Then making an impression of the print paste on the fabric by using any of the printing methods which is required.

How To Print On Fabric At Home 4 Different Ways So Sew Easy

How To Print On Fabric At Home 4 Different Ways So Sew Easy

Close Writing Text.

Printing text on fabric. Now iron it together. With the availability of commercially prepared fabric and inkjet printers its easier than ever to print words and letters directly onto fabric. You can print an array of words a poem or a saying and stitch or fuse them to a quilt.

Let your creativity fly as high as your ideas and design custom printed fabric. In properly printed fabrics the colour is bonded with the fibre so as to resist washing and friction. Cut out a section of freezer paper approximately 8 12 by 11 and iron it shiny side facing towards the fabric to the fabric until it adheres nicely.

At first fabrics should be pre-treated before printing. Give your fabric a good press using your iron with the steam setting off. Colors include red black and white.

Metal rollers are engraved with a pattern and dye reservoirs apply the color as needed. Textile printing is related to dyeing but in dyeing properly the whole fabric is uniformly covered with one colour whereas in printing one or more colours are applied to it in certain parts only and in sharply defined patterns. Printing performance depends on a well printing paste.

You can buy printable fabric sheets to use in an inkjet printer at many fabric and craft stores or you can print on cotton fabric with homemade printable fabric sheets. We offer direct printing on fabric with no minimum order no minimum number of colours exactly as you want it. Place the working side of the fabric onto the ugly old ironing board you have lying around.

I use a piece of printer cardstock as a pattern to make sure the size is exact. Get your custom fabric printed with your own design and create a unique fabric for your project. In other words the working surface is safely facing the bottom and the paper side of the freezer paper is facing you.

Writing Text Quilting Fabric Your Selections. Enjoy your new custom made fabric. Today we are going over different fabrics for printing on fabric preparing the fabrics print settings printing on fabric different heat.

Be sure to place the fabric either face-down or face-up depending on how your printer feeds the paper from the tray to the printing area. Textile printing is the process of applying colour to fabric in definite patterns or designs. After that drying is carried out on printed fabric.

From Sykel Enterprises this cotton print fabric features an all over Wisconsin pop art design and is perfect for quilting apparel and home decor accents. And this is how to print on fabric at home the easy peasy super affordable and quick way. Once youre absolutely certain the ink has dried 100 you can use steam on.

Fabric printing is a thing for you. Trim up the fabric and Freezer paper to exactly 8 12 by 11. Printing on the Fabric 1 Place the ironed sheet into your printers tray so it prints on the fabric.

You can start from a sample or a swatch. 5 Photo Fabric Printing Solution For this technique my friend Beckie from Infarrantly Creative shows you how to make a homemade solution to apply to your fabric before printing it. 100 Fabrics Cottons silks jerseys polys more.

Here are five techniques for writing on fabric and adding text to your textiles. But only if you used pigment inks as dye inks will fade andor smudge. Engraved roller printing is an industrial method for large print runs.

Now place the plastic side of the freezer paper down on that. In each of these methods the application of the colour usually as a thickened paste is followed by fixation usually by steaming or heating and then removal of excess colour by washing. The four main methods of textile printing are block roller screen and heat transfer printing.

Print photos and text onto fabric to create a permanent and washable image for use in quilts and other projects. Shop our selection of fabrics featuring script words phrases and more for home decor fashion and quilting. In printing wooden blocks stencils engraved plates rollers or silksc.

Jan 26 2021 - Explore Lucinda Poels board fabric printing followed by 1003 people on Pinterest. Lay your screen staple-side down on your fabric put a line of paint on the screen along one side and with your squeegee lay down a flood stroke using light pressure the next pass should be firm with a smooth motion to press the ink through the screen onto the fabric. In properly printed fabrics the colour is bonded with the fibre so as to resist washing and friction.

See more ideas about printing on fabric fabric prints. 10 check American Honor 2 check Andover Almost Blue 3 check Andover Northern Lights 3 check Andover Only You 3 check Andover Sun Print 2019 6 check Animal Friends 1 check Art Gallery. Textile printing is the process of applying colour to fabric in definite patterns or designs.

CottonBee is a fabric printing company. In printing wooden blocks stencils engraved plates rollers or silkscreens can be used to place colours on the fabric. Use 100 cotton fabric with a thread count of at least 200 and.

Printing paste must be prepared by using printing ingredients. I have not tried this technique myself but it looks like its an optimal method when printing Photographs on fabric. Digital printing is a favoured method for small batches of fabric as screen printing is an expensive process requiring space and specialist equipment.

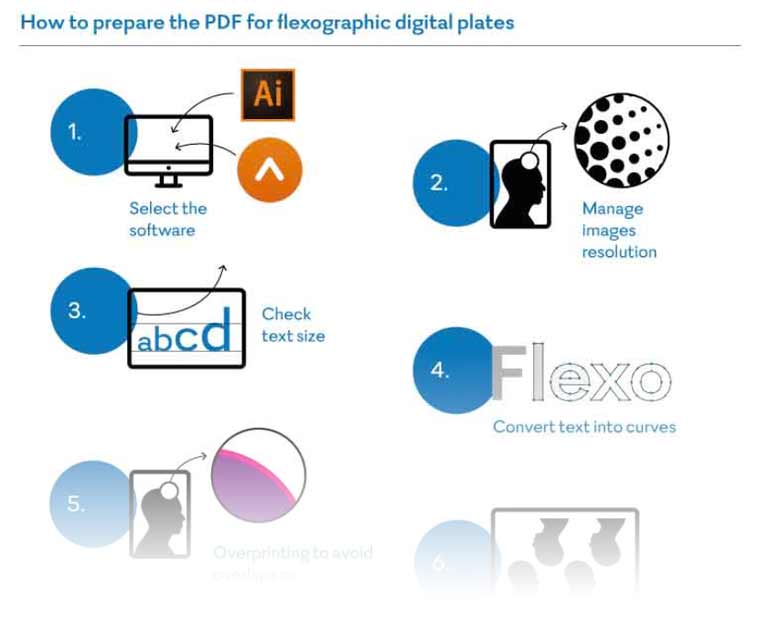

This traditional method of printing can be used on almost any type of substrate including corrugated cardboard cellophane plastic label stock fabric and metallic film. Guide on how to prepare a correct pdf for your plate with the online software.

Flexo 24 Great Innovation For Flexo Printing

Flexo 24 Great Innovation For Flexo Printing

Printing technology that is the ink is first transferred to an intermediate carrier rubber blanket and from there onto the substrate.

Flexographic printing process pdf. Flexographic writing is comparable to a rubber stamp and ink pad but more sophisticated and on. The FLEXOGRAPHY 101 Booklet Series is designed for anyone who needs a basic knowledge of different topics regarding the flexographic printing process. In short-run small format A3 size printing digital is taking over from offset for both color and BW printing.

Flexography This process adopts the same principle of relief printing and is there-fore similar to letterpress. Flexography is a roll-feed web printing process. Fly-specks also appear in the process areas.

They are specified by their line screen or the number of cells per. Flexographic plates can be created with analog and digital platemaking processes. SC6-0204 12902 531 PM Page 8.

This also means. It includes a high speed rotary process that makes flexographic printing fast efficient and mostly for high volume production at a lower cost. Letterpress is still used to some extent for embossing imprinting and special-purpose reproduction.

Flexographic printing is not heat sensitive. It is for good reason that flexographic printing is the most common technique. Flexographic printing can be done on any substrate.

Heat sensitivity of the materials to be printed on is not an issue with flexographic technology. The inking unit can be either of fountain roll system or doctor blade system. Flexographic printing is significantly faster than digital making large runs of labels more cost-effective to print on flexo presses.

As opposed to the secondary die-cutting folding or laminating processes used by offset printing flexographic printing integrates these processes into a single pass. Flexography prints items that we are connected with daily including cereal boxes bottle labels crisp bags foodstuff bags corrugated boxes newspapers and grocery bags. Flexography is a modern version of letterpress printing.

Flexographic printing commonly termed flexo is a process derived from the letterpress process that was described above. ArtPro a software distributed by Esko and designed to generate pdf files for flexo. The flexographic printing process uses quick-drying semiliquid inks.

The fountain roll system is a simple old system yet if there is too much or too little ink this system would likely not control in a good way. The price of flexo printing plates is relatively high compared to other types of plates but they last for millions of impressions if they are properly cared for. The disadvantages of flexo printing.

Printing Process The relief plate used for flexography is made of molded rubber or photopolymer materials with the image areas raised above the non-image areas of the plate. Flexible Printing Plates In this case printing plates are thin sheets of polymer material laser engraved with an image of your digital artwork. It is a direct printing process which means that ink is transferred directly from the printing surface to the substrate.

Those new to the industry will benefit from the easy-to-follow explainers of topics crucial to flexography. The main difference with both processes is that offset printing is only done on flat surface while Flexographic printing can be used on almost any substrate with a flexible surface. The main differences are the use of a flexible printing plate as the image carrier the method of application of ink to the plate and the ink itself.

Flexographic printing is commonly used to print high volumes of labels and packaging. FLEXOGRAPHY PRINTING PROCESS Flexography could be a versatile process which will print on a range of materials of varying sizes. Flexographic printing Flexography is a process in which the printing image stands up in relief.

It is a relief process. Flexography uses rotary flexible plates to directly print on the substrate rather than printing indirectly through a series of offset plates as is the case in offset printing. Flexo is used on a wide range of substrate materials including direct thermal media yielding superior quality graphics and ANSI A grade barcodes.

The gaps between dots are bridged by ink. Flexography is a direct printing method in that the inked plate applies the image. Flexible Packaging Printing Processes Overview Slide 23 2009 Consumer Packaging Solutions For Barrier Performance Course FLEXOGRAPHY Printing - anilox rolls The anilox roll is a steel or aluminum core cylinder with a ceramic surface that contains millions of very fine cells.

Presses can print on a variety of films foils papers corrugated board and paperboard and achieve speeds of 500 to 2000 feet per minute. FLEXOGRAPHIC INKSFLEXOGRAPHIC INKS DIRTY PRINTINGDOT BRIDGING Appearance of a dirty grainy effect as a result of two or more process dots linking together. Version changes are time-consuming to make.

Digital printing is increasingly utilized for print jobs that were previously printing using offset flexo or screen printing. Flexo 24 has a pre-flight software that prepares files for producing your flexo plate. Flexography is a roll-feed web printing process.

The high throughput flexographic process was used to print fine lines on the front side of silicon solar cells in order to develop a seed and plate metallization scheme. A liquid is used which may be. To generate pdf files for the production of photopolymer plates different types of programs are availableSome of these are.

Flexography Ink Control The ink is controlled in the flexographic printing process by the inking unit.